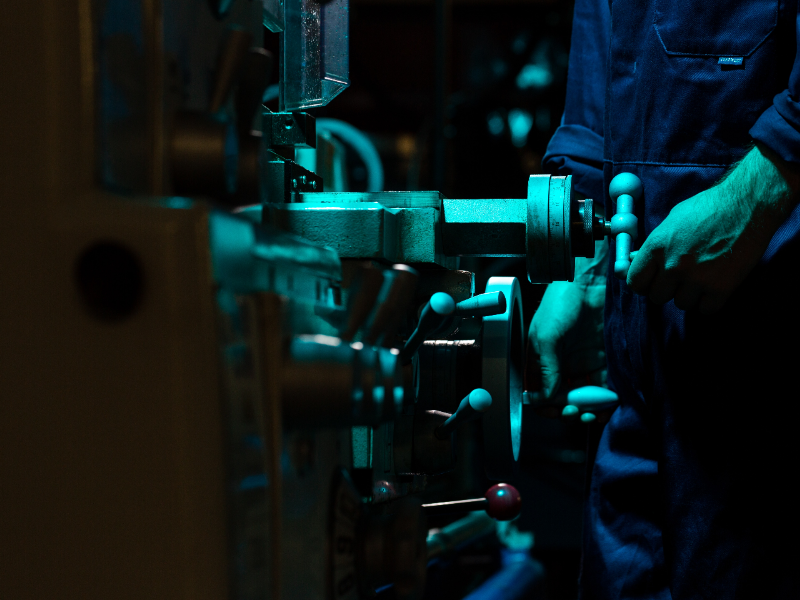

Machinery and Engineered Products

The fluctuating order volumes, reduced internal value generation, heightened competitive pressure, and more intricate interconnections of value creation processes are placing increasing pressure on manufacturers of machines and plants. In response to these challenges, the role of procurement has progressively gained importance in recent years.

Unstable starting conditions and growing competitive pressure

Manufacturers of machines and plants are currently encountering several challenges that are critical to their profitability. Above all, they must deal with highly fluctuating order volumes, while batch sizes are becoming smaller, making the processes significantly more complex. This complexity is further exacerbated by the reduction in internal production scope and a more intricate interconnection of value creation structures.

The pressure of competition and costs has also been steadily increasing in recent years, particularly due to the strong competition from companies in Asian countries, which have become major competitors in the field of innovation. Additionally, rising raw material prices and tight supplier markets contribute to this challenge.

Transform your procurement into a value driver

Companies in the mechanical and plant engineering sector primarily thrive on their technical innovations and solutions. Therefore, engineering naturally holds a high priority within the company, especially for traditional, medium-sized enterprises. An efficient procurement organization can also contribute significantly to the company's success and enhance its overall resilience.

With our extensive industry expertise, we help your procurement function establish itself as a value driver. In our projects, we take a cross-functional approach, utilizing various technical methods alongside commercial levers for optimization. Additionally, we assist you in the area of Indirect Spend, which is often overlooked based on our experience.