Overtake the competition with your own standards

The past months have shown: Political crises, trade restrictions, currency fluctuations and many other external influences make efficient raw material procurement more difficult. External factors such as massively increased stock market indices and accelerated inflation have a much greater impact on success in commodity procurement than is the case with other commodity groups. Structured risk management should therefore be an integral part of any commodity strategy.

Particularly in the current situation, characterized by supply bottlenecks and volatile prices, you can create greater planning security and competitive advantages by establishing a professional commodity and risk management system.

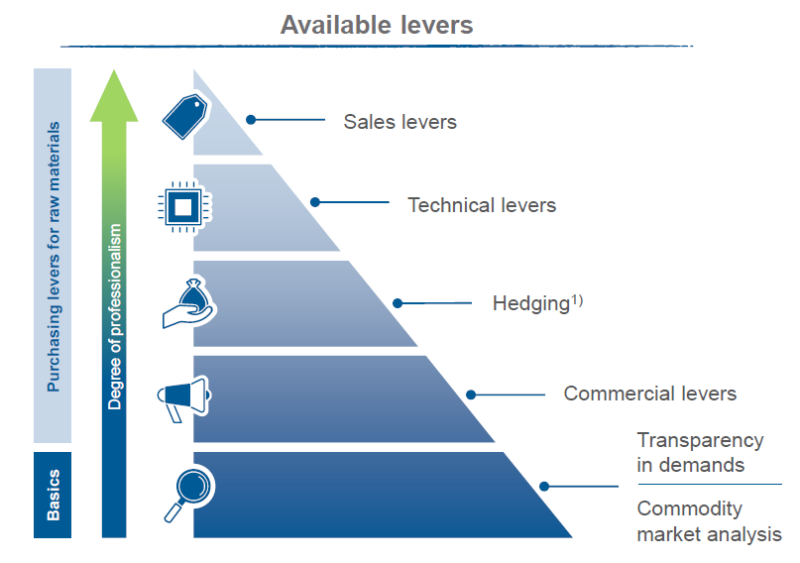

Usingour many years of consulting experience in raw materials procurement, we have identified the four most important levers thanks to which our customers are well positioned, despite the current difficult market conditions. We divide raw material management into sub-disciplines in order to build a fully comprehensive and sustainable raw material procurement system.

PROCUREMENT: LET’S GET REAL!

Our expert Justus on the topic of raw material management

How do we go about advising on raw material procurement?

In the raw material market analysis, on the one hand, the market development of raw materials and on the other, the market of raw material suppliers are continuously analyzed by our raw material experts. Thanks to our in-depth knowledge of raw material management, our data is always up-to-date and ranges from raw material requirements for the food industry or the pharmaceutical sector to industrial goods, the automotive industry or the electronics industry. In addition, we create demand transparency in your raw material procurement in order to achieve the best possible efficiency in procurement optimization. In doing so, we perform quantity and cost breakdowns, create a raw material spend matrix and broaden your perspective by creating transparency across your supply chain.

Commercial levers include demand-specific tenders and corresponding negotiations to identify suitable alternative suppliers for your requirements. In the process, individual contract designs are developed andare predominantly aimed at securing stable supply security at optimal costs.

Hedging is a proven solution to protect against price fluctuations and supply bottlenecks. We distinguish between physical hedging, operational hedging, supplier hedging and financial hedging. Targeted hedging measures minimize price and supply risks. We work with you to develop and implement the appropriate hedging strategy for your raw material procurement.

The use of technical levers opens up additional potential in cost management and ensures a reduction in raw material dependency. We achieve this by reducing the use of raw materials, reviewing and, if possible, using substitutes and developing new products.

Aligning procurement and sales strategies offers additional potential for minimizing price risks. Our raw material consultants support the specialist departments in the joint development of strategies. Coordination between procurement and production and open-book costing harmonize price conditions and ideally pass on risks to customers. The targeted sale of alternative products also ensures greater security in your Raw Material Management.

Raw materials workshop

An intensified use of recycled materials would reduce Europe’s dependence on the countries where the raw materials are stored or refined.

Justus Brinkmann, Senior Project Manager, KGM Strategy Cologne

The results

- Cost optimization in raw material procurement

- Minimization of raw material risks (supply and price risks) through optimization of existing as well as negotiation of new supplier contracts

- Establishment of tools and knowledge to ensure long-term stable raw material management and rapid responsiveness to market changes

Our raw material experts